For bulk liquid transfers in multiwell microplates, the UCSC CSC has one device that performs all the functions, as well as two specifically for plate washing and three specifically for dispensing, and three of these have plate stackers.

I. BioTek EL406 washer/dispenser with BioStak4

Basic information:

- Make/Model: BioTek EL406

- What makes it special compared to other plate washers/dispensers: can be programmed with the computer software to perform complex sequential tasks, fast, and can do 1536-well plates.

- Capabilities in brief: In order to have multiple dispensing and aspirating capabilities on one device, this is an instrument with many different components doing different things. Please expand the tabs below of interest to you for more information.

- It is operated by a PC with LHC software (or using the LED screen interface on the instrument if you wish). The dispensing stage has optional troughs for reclaiming precious reagent. The waste has a secondary containment and a sensor, connected to a high speed, silent vacuum pump, the Vacubrand ____.

- Three different wash manifolds for aspirating multiple wells at once, two of which have dispensing manifolds attached. The washer module has a sonicator for deep cleaning. The washing system is connected to a buffer switching module (e.g. can switch between a water rinse and priming/washing with

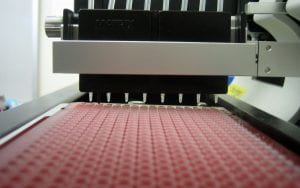

- PBS without user intervention). The plate washing module is the same as described below for the ELx405, except that in addition to the 96/384-combo washer module, we have purchased a module specifically for washing 384-well plates (with 192 tubes instead of 384) and a module specifically for aspirating from 1536-well plates (and it works with the peri pump 1ul dispenser).

- Two separate syringe pump-driven dispensers that apply the same liquid to all rows in the plate but can be programmed by column. We currently have 8 cartridges for the syringe pumps designated for specific types of liquids, which can do 384 or 1536 well plates. Cartridges come in wide bore or (for liquids with detergent) narrow bore.

- Two separate peristaltic pump-driven dispensers. We currently have 1ul, 5ul, and 10ul cassettes that each have 8 separate tubes corresponding to different rows, and can also be programmed by column. The 1ul cassette can dispense down to 0.5ul and can be used with 1536 format plates.

- For high throughput: Integrated with a BioStak4 that has an arm that delivers microplates in the order in which they are stacked. Is a smarter model than the original BioStak found on the instrument below. Use of the BioStak4 is optional.

At the output side, a manifold will dispense into your microplate. You must select the appropriate manifold for your

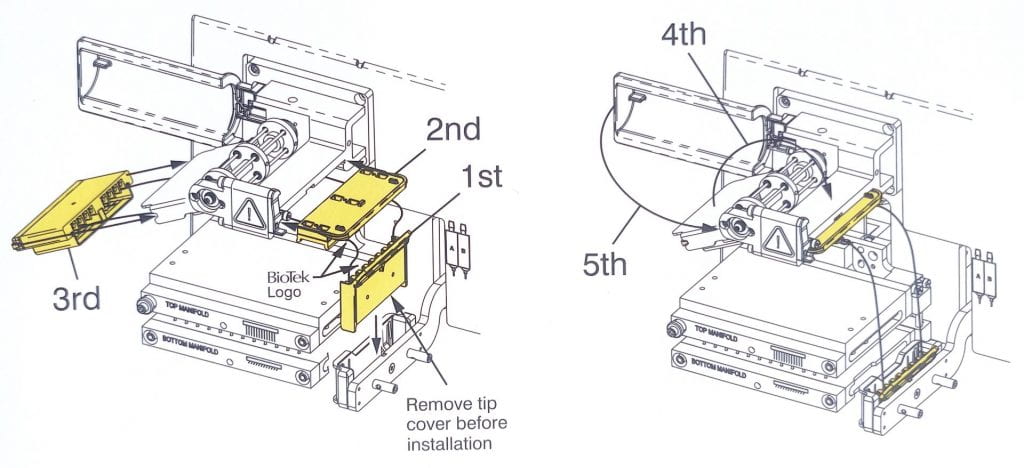

At the intake side, where you dip the tube into your cells or buffer to be dispensed, there are "check valves" that control the direction that the liquid flows (one flows from the bottle/Erlenmeyer to the syringe, another flows from the syringe to the dispense manifold). Please make sure you connect the check valves in the correct orientations! Picture below. Please select the appropriate check valves for what you are dispensing. The orangey check valves are AUTOCLAVABLE (do not pass DMSO through them! Reorder PN 68083) whereas the white check valves are SOLVENT RESISTANT (do not autoclave. Reorder PN 68073). If there is wear and tear on the check valves, you can order them separately with the part numbers indicated above (you need two per syringe pump) or as sets with the tubing connected (everything you need on the intake side for two syringe pumps). Either way you need the silicone tubing – they also sell sets with solvent-resistant teflon-coated tubing but they DO NOT WORK (do NOT buy PN 7180541). Silicone tubing with solvent-resistant check valves is PN 7183002.

Resources:

- » Video taken in the CSC of how to clean the syringe manifold

- » YouTube video of what the EL406 does.

- EL406 official user manual from Perkin Elmer (379 pages PDF)

- BioStack4 user manual from Perkin Elmer (440 pages PDF)

- LHC software instructions incl mostly installation from Perkin Elmer (22 pages PDF)

- Instructions for replacing the tubing inside the peri cassettes (5 pages PDF)

- Instructions for calibrating the peri cassette (8 pages PDF)

- Instructions for the waste drain system (6 pages PDF)

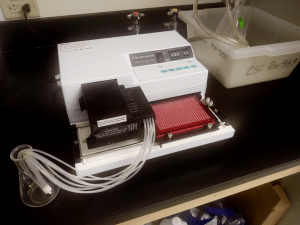

II. BioTek ELx405 washer with BioStak

Basic information:

- Make/Model: BioTek ELx405

- What makes it special compared to other plate washers/dispensers: aspirates from or dispenses to 96 wells at a time.

- Capabilities in brief: A 96-tube dual wash manifold can wash 96-well plates (in one pass) or 384-well plates (by performing four passes for the four quadrants). It has one set of straight long tubes for aspirating and one set of shorter, angled tubes for dispensing. The waste has a secondary containment and a sensor, connected to a vacuum pump. The device is operated by an LED screen interface on the instrument. Alternately, a computer can be connected to it, for scheduling more complex tasks.

- For high throughput: Integrated with a BioStak that has an arm that delivers microplates in the order in which they are stacked.

» VIDEO! of the Bio-Stak and plate washer in action

III. BioTek ELx405 washer

Basic information:

- Make/Model: BioTek ELx405

- What makes it special compared to other plate washers/dispensers: aspirates from or dispenses to 96 wells at a time. The user manually loads plates one at a time. It can be used in conjunction with the other nearly identical plate washer(s) to increase speed, by dividing your stack of plates between the two instruments. Or they simply serve as redundant backups for if one or the other experiences a clog or leak in the manifold, or other issues that occasionally arise during operation.

- Capabilities in brief: It has one set of straight long tubes for aspirating and one set of shorter, angled tubes for dispensing. The waste has a secondary containment and a sensor, connected to a vacuum pump. The device is operated by an LED screen interface on the instrument. Alternately, a computer can be connected to it, for scheduling more complex tasks.

- For high throughput: A 96-tube dual wash manifold can wash 96-well plates (in one pass) or 384-well plates (by performing four passes for the four quadrants). It performs a sequence of aspirate-dispense steps as programmed – no need to hand pipet.

» VIDEO! of this plate washer in action

IV. BioTek MultiFlo dispenser

Basic information:

- Make/Model: BioTek MultiFlo

- What makes it special compared to other plate washers/dispensers: fast, can do 1536-well plates, and has a very easy to learn touchscreen interface.

- Capabilities in brief: It is operated by a PC with LHC software, or via the PlateWorks software and robot, or using the LED touchscreen on the instrument. Two separate syringe pump-driven dispensers that apply the same liquid to all rows in the plate but can be programmed by column. We currently have several cartridges for the syringe pumps designated for specific types of liquids, which can do 384 or 1536 well plates (the same cartridges as the EL406). One peristaltic pump-driven dispenser can be loaded with 1ul, 5ul, or 10ul cassettes (the same cassettes used by the EL406 above) that each have 8 separate tubes corresponding to different rows, and can also be programmed by column. The waste simply drains by gravity.

- For high throughput: Integrated with a Flex robot at the Perkin Elmer Explorer G3 Workstation that can deliver random-access plates and combine workflows with our other integrated devices (see the Explorer site for details). Use of the robot is optional. When loading the cassette, or for walk-up use, it is installed on a drawer to help with access, and there is a light above the device.

For further information:

- MultiFlo user manual from BioTek (415 pages PDF)

- See above for the EL406 – the MultiFlo has the same hardware components except for the wash manifold and the waste system.

- See the page all about the Explorer system, on which the MultiFlo is integrated.

V. Matrix Wellmate dispenser

Basic information:

- Make/Model: Matrix Wellmate

- What makes it special compared to other plate washers/dispensers: the stacker is part of the instrument, delivering plates directly from the stack to the plate surfboard (no robot arm unlike the BioStak or Flex).

- Capabilities in brief: The device is operated by an LED screen interface on the instrument. One peristaltic pump-driven dispenser can be loaded with cassettes that each have 8 separate tubes corresponding to different rows, and can also be programmed by column. These cassettes are not the same as any other device in our inventory – they have a larger dead volume. The waste simply drains by gravity.

- For high throughput: includes a stacker that delivers microplates in the order in which they are stacked. This particular stacker is especially easy to load and unload.

- » VIDEO! Of our WellMate in action

VI. Thermo MultiDrop dispenser

Basic information:

Make/Model: Thermo Electron Corporation Finstruments Multi Drop 384 Product 5840157

Make/Model: Thermo Electron Corporation Finstruments Multi Drop 384 Product 5840157- What makes it special compared to other plate washers/dispensers: it is small enough to be placed inside a cell culture hood or chemical fume hood relatively easily.

- Capabilities in brief: The device is operated by a few simple buttons and switches. One peristaltic pump-driven dispenser can be loaded with cassettes that each have 8 separate tubes corresponding to different rows. It dispenses 5ul to 395ul, including water, alcohol, protein solutions, cell suspensions, etc. These cassettes are not the same as any other device in our inventory – we have four of them available that are designated for specific substances to prevent cross-contamination (e.g. bacteria, LPS, mammalian cells). The waste has to be collected by manually aspirating from the small collection trough (otherwise it wets a sensor and the device has to be disassembled and cleaned!). It can be programmed to do any number of columns, starting at the left side of the plate as loaded (to dispense to the right side of the plate only, simply load the plate in flipped orientation). Or it can step between columns manually to dispense into any individual column at a time.

- For high throughput: Our least sophisticated dispenser – but it is still faster and more reproducible than to hand pipet!

- Not currently available, but possible: It is compatible with robotic integration, but has been kept as a stand-alone device; it is also compatible with being operated by a PC via FiLLIt software.

- Some videos of MultiDrop are available here although most are filmed with different models than ours.

Further information:

- Multidrop cassette calibration

- Thermo Fisher Scientific technical note TN-ALH-MDcombi01-0209 with lots of tips on dispensing cells, frothing, clogging, etc.

- Thermo Fisher MultiDrop Customer Corner

- Click on Reagent Atlas for list of compatible solutions

- Click on Maintenance for instructions on operating and maintaining the cassettes and device

- There are further useful bits on this site including FAQs.

- Thermo Scientific technical note COL114200 0421 about reproducibility of live cell dispensing in a MultiDrop. The CSC recommends to constantly mix the cell suspension to ensure even plating.

- Thermo Scientific product note about life time expectancy of MultiDrop cassettes

- Thermo Scientific product tips about clogs in MultiDrop