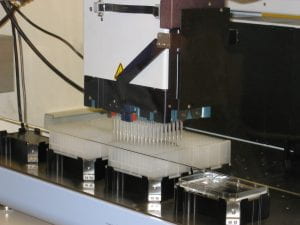

The UCSC CSC has one semi-automated multichannel pipet, and three pipetting robots. These each consists of 3 components: (1) a pegboard-type deck, on which you can lay any configuration of plates/tips/reservoirs/etc, (2) a robot arm, and (3) at the end of the arm a pipet, gripper, and/or pin tool for performing the desired transfer functions. Our latest is the Rainin MicroPro (96 tip head P300), then the Eppendorf epMotion (one tip head); we recently upgraded the Janus MDT (96 tip head P200 and pin tools – 100nl 384 pin tool is best); and we also have a Janus Varispan (8 individually controlled tip heads).

The UCSC CSC has one semi-automated multichannel pipet, and three pipetting robots. These each consists of 3 components: (1) a pegboard-type deck, on which you can lay any configuration of plates/tips/reservoirs/etc, (2) a robot arm, and (3) at the end of the arm a pipet, gripper, and/or pin tool for performing the desired transfer functions. Our latest is the Rainin MicroPro (96 tip head P300), then the Eppendorf epMotion (one tip head); we recently upgraded the Janus MDT (96 tip head P200 and pin tools – 100nl 384 pin tool is best); and we also have a Janus Varispan (8 individually controlled tip heads).

I. RAININ MICROPRO

Basic information:

- Rainin MicroPro 300

Resources:

»VIDEO! how to load and unload tips on our MicroPro

- User manual from Rainin (76 pages PDF)

II. EPPENDORF EPMOTION

Basic information:

- Eppendorf epMotion 5070

Resources:

- 2021 hardware manual from Eppendorf (150 pages PDF)

III. JANUS MDT

Basic information:

- Nickname: pinning robot

- Perkin Elmer Janus Modular Dispense Technology workstation G3

- a robotic liquid handler that performs X-Y-Z robotic functions.

- It has an MDT (modular dispense technology) head equipped with a 96-channel pipette for compound transfer using disposable tips and controllable volume. It transfers all 96 samples at once, all at the same volume, to the same locations (also known as “plate stamping”). This is useful for reformatting compound libraries. When using tips, special compatible “robo-rack” tips must be used. It is possible to wash the tips to cut down on costs (we recommend 10 or fewer uses per tip).

- It also has 96- and 384-pin tools from V&P capable of delivering fixed volumes (e.g. 10 nl, 100 nl, or 500 nl) to multi-well plates (96, 384, or 1536). The pin wash sequence we use is: dunk in 70% ethanol, blot on lint-free paper, sonicate in DMSO, hover over a bubbler that sprays 100% ethanol up into each pin notch, blot, and air dry. The instrument is connected to an ethanol carboy, a waste carboy, and two peristaltic pumps to allow clean ethanol in, and waste ethanol out. A quad AC control box automates the pin tool wash steps.

- The tips, tools, plates, reservoirs, etc. are distributed in a user-defined arrangement across two metal peg board decks. You can program any sequence of steps between the on-deck items, and manually swap them out as needed (e.g. swap for a fresh tip box).

- It is equipped with a PlateStak and PlateID Microscan MS-710 barcode reader for high throughput applications.

- It is connected to an air compressor that is used by the robot arm as well as by a blower for drying steps.

- Operated by WinPREP software.

» VIDEO! our pinning robot in action! (this YouTube video has no sound)

» YouTube video from another lab of a similar Janus MDT performing a simple 96 well pipetting task.

Pinning robot calibration detailed instructions.

IV. JANUS VARISPAN

Basic information:

- Nickname: cherry picking robot

- Perkin Elmer Janus Varispan workstation G3

- an X-Y-Z robotic liquid handler with an independently controllable 8-tip pipet. It is for more complex/custom tasks as compared to the MDT, most commonly for performing serial dilutions or compound cherry picking. It can be programed to perform almost any imaginable routine automated liquid handling task. Special compatible tips must be used, and can be washed to reduce costs if desired. Operated by WinPREP software.

- Currently located under an exhaust hood in PSB 365 to enable use with hazardous chemicals!

>>YouTube video of a Perkin Elmer rep checking and calibrating the XYZ positioning of a similar Janus Varispan system.

Resources for both Janus robots:

- Janus user guide from Perkin Elmer (437 pages PDF)

Interested in chemical compatibility of polypropylene? See the chart here.